Projet NEWIRON

Production d’acier durable par réduction de minerais de fer à partir d’hydrogène renouvelable

Projet coordonné par le CNRS

Durée de 4,5 ans

3 millions d’euros de budget

Thèses

Contexte et enjeu

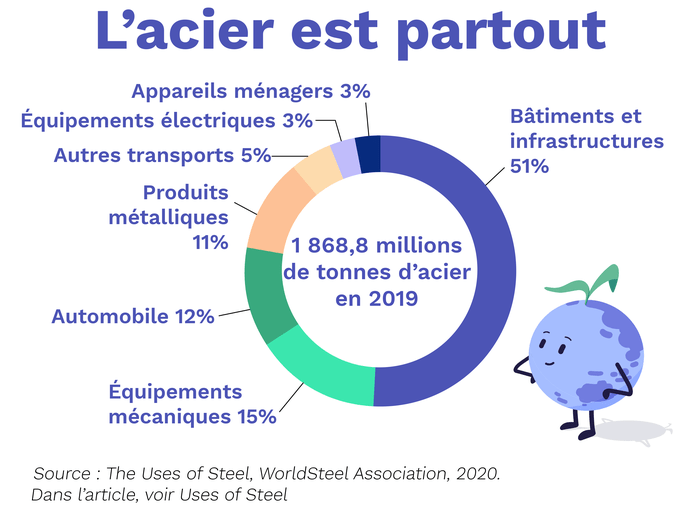

L’acier est le matériau de base de la civilisation moderne. Bien qu’il favorise la durabilité grâce à ses taux élevés de recyclabilité, sa production primaire a de fortes répercussions négatives sur l’environnement. En moyenne, chaque tonne d’acier brut produite s’accompagne d’une quantité stupéfiante d’environ 2,1 tonnes de CO2. Ce chiffre énorme représente actuellement ~8% de toutes les émissions de CO2 sur la planète et fait du secteur de la fabrication du fer le plus gros émetteur industriel de CO2. En effet, le fer est actuellement extrait de ses minerais au moyen de réactions chimiques d’oxydoréduction qui utilisent des substances porteuses de carbone comme agents réducteurs, ce qui fait du CO2 le principal sous-produit. Pour lutter contre le réchauffement climatique, une réduction drastique de 80 % de toutes les émissions d’ici à 2050 est nécessaire et il faut s’attaquer aux sources les plus polluantes.

Il est donc impératif d’explorer et de mettre en œuvre de toute urgence des voies nouvelles et durables de fabrication du fer dans les décennies à venir.

Objectifs scientifiques

Le projet NEWIRON vise à étudier le remplacement du carbone par des gaz contenant de l’hydrogène, produits à partir de sources renouvelables, pour servir d’agents réducteurs pour les minerais de fer. Dans ce cas, l’eau est le sous-produit direct plutôt que le CO2. NEWIRON se concentrera particulièrement sur trois voies alternatives, chacune d’entre elles ayant actuellement des niveaux de maturité technologique (TRL) très différents : la réduction directe à base d’hydrogène (DR), la réduction par fusion au plasma d’hydrogène (HPSR), et la réduction solaire à base d’hydrogène (SDR) via le chauffage solaire concentré. Nous visons ici à relever les défis émergents dans ces voies. En ce qui concerne la réduction par fusion, la rareté croissante des concentrés de minerai de fer à haute teneur pose des difficultés pour la production de boulettes de haute qualité destinées à alimenter les fours à cuve.

Par conséquent, les minerais de fer à faible teneur devront servir de source alternative de fer. NEWIRON propose d’étudier la réduction directe des minerais de fer à forte teneur en impuretés (SiO2, Al2O3) dans le but de mettre en lumière les transformations chimiques secondaires concurrentes et leur impact sur la cinétique de réduction globale. Deuxièmement, il est possible que, pour des raisons économiques et techniques, une partie du futur hydrogène vert soit transportée sous forme d’ammoniac (NH3), un vecteur d’hydrogène à haute densité. L’utilisation de l’ammoniac pourrait également être avantageuse en termes de température d’activation et de protection contre le gel.

Les équipes du projet vont étudier la réduction directe du minerai de fer par l’ammoniac (NH3). La HPSR n’a été étudiée que dans des réacteurs possédant une seule électrode DC. Nous proposons ici la réalisation d’expériences HPSR à l’échelle du laboratoire à l’aide d’un réacteur à 3 électrodes en courant alternatif. La nécessité d’une telle étude est évidente lorsque l’on envisage d’adapter les fours à arc électrique existants et déjà opérationnels à des fins de plasma d’hydrogène. Puisque le HPSR ne nécessite que de l’H2 dilué (max. 10% H2), le projet cherche à identifier et à tester des gaz de dilution alternatifs et bon marché, tels que ceux issus de la pyrolyse autothermique de la biomasse (CO, CO2, H2, CH4, N2). L’utilisation directe de l’énergie solaire est probablement la voie parmi les trois où les émissions de CO2 pourraient être les plus faibles, bien qu’elle n’en soit qu’à ses débuts. NEWIRON propose de construire un réacteur pilote pour maximiser le rendement de réduction sous irradiation solaire concentrée en utilisant à la fois H2 et NH3 comme agents réducteurs. L’objectif principal de l’étude de ces trois voies différentes étant d’atténuer le changement climatique et d’autres impacts environnementaux, une analyse du cycle de vie (ACV) et une optimisation de chaque processus alternatif seront réalisées (y compris la production de réactifs, l’approvisionnement et le stockage, la construction d’infrastructures et d’équipements). NEWIRON vise à fournir des résultats scientifiques pour développer le TRL de ces trois voies alternatives et C-lean de réduction à base d’hydrogène, contribuant ainsi à réduire les émissions de CO2 dans le secteur de la sidérurgie.

Le consortium

Plus de projets