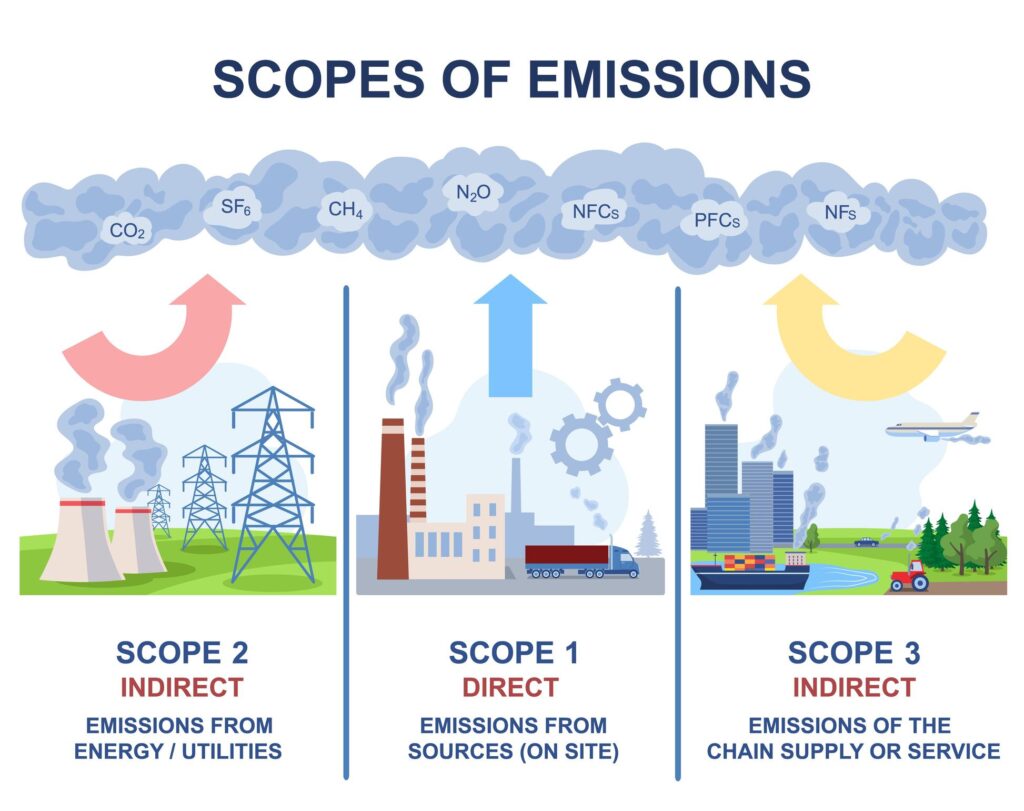

Understanding CO₂ emission scopes: a key framework for decarbonizing industry

In industrial decarbonization strategies, measuring greenhouse gas emissions is a key step. The most widely used framework today is that of emissions scopes, derived from the Greenhouse Gas Protocol[1]. It allows CO₂ (and other GHG) emissions to be classified according to their origin in the value chain.

A clear understanding of these scopes is essential for prioritizing actions, guiding research, and avoiding blind spots in carbon neutrality trajectories.

Scope 1: Direct emissions from the industrial site

Scope 1 includes emissions generated directly by the company’s facilities. In industry, these mainly consist of:

- from the combustion of fossil fuels in furnaces, boilers, reactors, or turbines,

- emissions linked to industrial processes (cement, steel, chemicals, refining),

- fugitive emissions (gas leaks, solvents, refrigerants).

Scope 1 is often at the heart of technological barriers. It mobilizes levers such as process electrification, low-carbon hydrogen, carbon capture and storage (CCS), and innovation in materials and processes themselves.

Scope 2: indirect emissions related to purchased energy

Scope 2 covers emissions associated with the production of electricity, heat, or steam purchased by the industrial site. These emissions are not produced on site, but are induced by its energy consumption.

Even though these emissions may decrease with the decarbonization of the electricity mix, they raise crucial questions:

- robustness of low-carbon electricity supplies,

- flexibility and management of industrial demand,

- trade-offs between direct electrification and other energy carriers.

Scope 3: emissions from the value chain, often the majority

Scope 3 includes all indirect upstream and downstream emissions:

- extraction and production of raw materials,

- transport and logistics,

- use of products by customers,

- end of life, recycling, and recovery.

In many industrial sectors, Scope 3 accounts for the majority of total emissions, sometimes more than 70–80%.

Scope 3 opens up complex but strategic areas of work:

- eco-design and material efficiency,

- circularity, recycling, and material substitution,

- changes in uses and economic models,

- robust and harmonized quantification methods.

Complementary scopes, not competing ones

It would be a mistake to pit these scopes against each other: they are complementary. A credible industrial decarbonization strategy must:

- prioritize direct emissions (scopes 1 and 2),

- while gradually integrating scope 3 into a value chain and cooperation approach between stakeholders.

For research, this framework highlights the need to develop integrated approaches combining process innovation, energy modeling, life cycle analysis, and economic science. This involves combining disciplines and scales: from industrial processes to energy systems, to economic and territorial dynamics.

In 2024, France’s territorial emissions amounted to approximately 369 Mt CO₂e, down by around 32% compared to 1990 [1]. However, its carbon footprint, which includes imported emissions linked to consumption, will reach around 563 Mt CO₂e, nearly 50% more than domestic emissions alone. This difference illustrates the significant weight of indirect emissions outside the country, conceptually similar to a “scope 3” at the national level, although the methodological frameworks differ.

Towards coherent industrial trajectories

Scopes are not just a reporting tool. They structure investment decisions, technology roadmaps, and public policy. Understanding them better means better identifying where research can have the greatest impact in accelerating the decarbonization of industry.

More news News