A new European project for SHIP4D: SOLDEM officially accepted

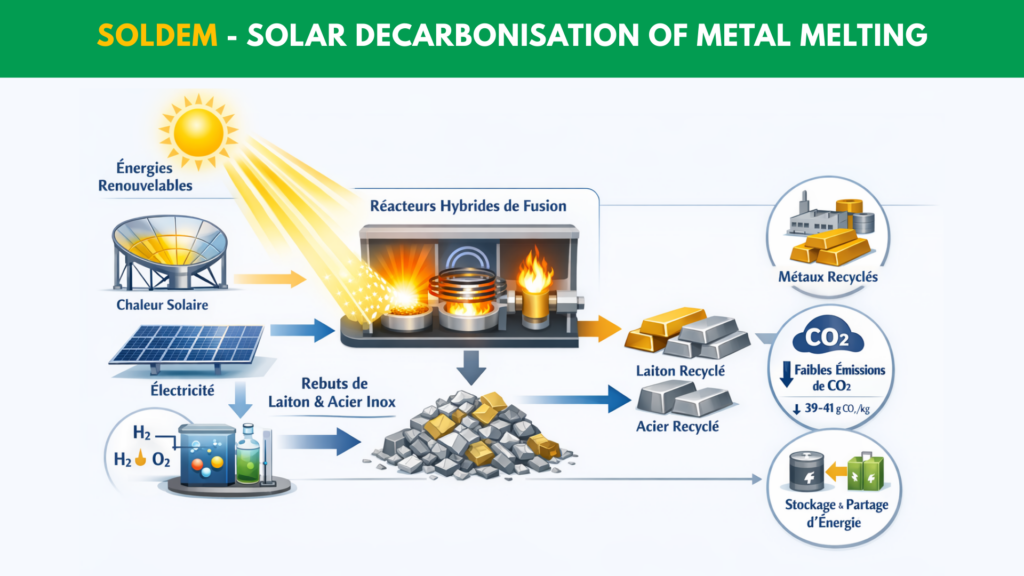

SOLDEM (Solar Decarbonisation of Metal Melting) will demonstrate the world’s first solar-hybrid melting process for brass and stainless-steel scraps, replacing fossil-based furnaces withan integrated renewable solution. By combining concentrated solar heat, renewable electricity, and solar hydrogen, SOLDEM will provide a constant, robust, low-carbon energy input to energy-intensive metallurgy. The project will validate two 350 kW hybrid reactors (solar-induction/arc and H2/O2 burner), supported by a high concentration solar furnace and a 60 kW photoelectrochemical device for generation of H2/O2. Together, those component models will be integrated into a digital plant simulator fed by experimental data to de-risk scale-up.

SOLDEM will enable :

- enable the integrated use of multiple renewable carriers (solar heat, electricity and green H2) in industrial sites

- foster circular industrial cooperation through scrap-to-product loops and energy sharing

- support grid stability via hybrid short- and long-term storage

- implement ESPR-compliant renewable energy labelling and traceability

- demonstrate technical and economic feasibility with CO₂ emissions as low as 39–41 gCO₂/kg (80–93% reduction vs electric furnace) at competitive costs (0.20–0.83 €/kg) and ESPR-aligned business cases with ROI < 2 years

The SOLDEM validated plant is expected to produce 1510–2670 t/y brass and 1090–1850 t/y stainless steel from locally collected machining scraps, cutting dependency on imports, reducing industrial emissions, and reinforcing industrial regional clusters.

The SOLDEM consortium unites leading research centers (CNRS, DLR, KUL, CENER), SMEs (Panatere, Bulane, SOHHYTEC, CSP-Boost), and industrial users (Radiall, Amphenol, Socrate, RINA), ensuring excellence from technology to market replication. SOLDEM will pave the way for competitive, renewable and circular metallurgy in Europe, strengthening industrial resilience and leadership in climate-neutral value chains.

More news News