Methanisation: a key solution for decarbonisation of the industry?

France, with more than 1,300 biogas plants in service as of January 1, 2023, is positioned as a world leader in this field. Its biomethane injection site park is the largest in Europe and in the world, with a production capacity of 12 TWh of biomethane, equivalent to two nuclear reactors (figures as at 31 December 2023). This position is a major asset in the context of energy transition and decarbonisation of the industry.

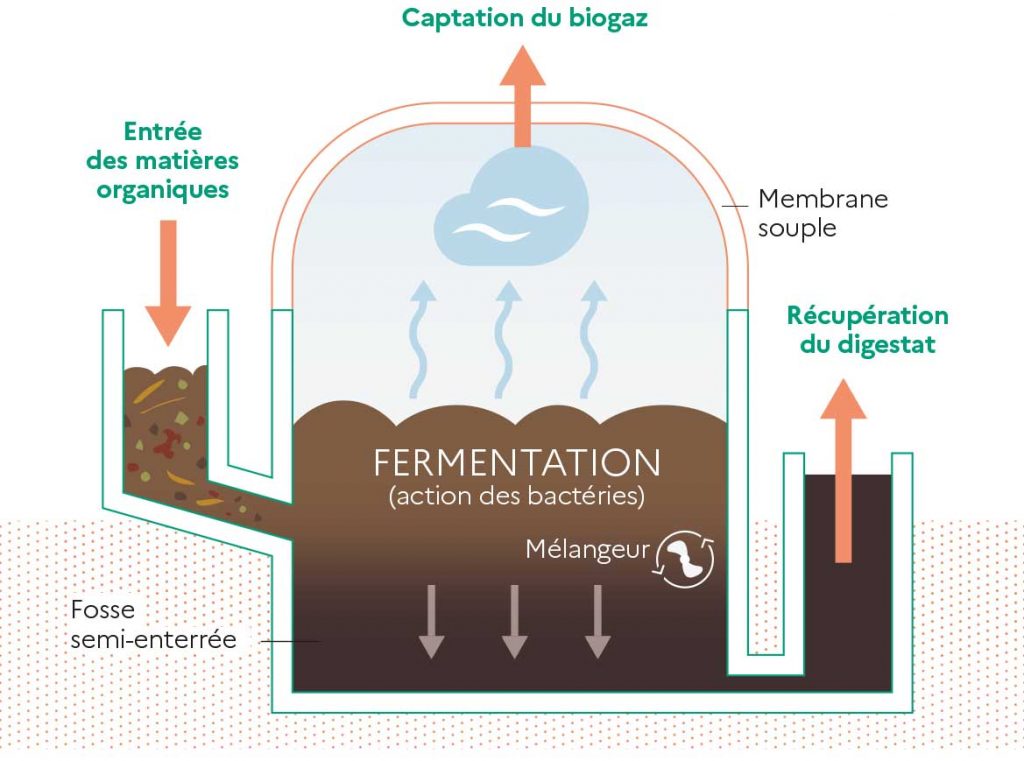

Methanisation is the capture of methane generated by anaerobic (oxygen-free) degradation of organic matter. The biogas produced can be converted into electricity and heat in cogeneration plants, or injected directly into the gas network. The remaining residue, called digestat, is used as fertilizer to enrich soils. This process also has multiple benefits for industry, particularly in reducing greenhouse gas emissions:

- Production of biomethane to replace fossil fuels

Biomethane, once purified, can be used in industry to replace fossil fuels such as natural gas or coal. It can be injected into the gas grid or directly used as an energy source in industrial processes. This substitution contributes directly to reducing dependence on fossil fuels and CO2 emissions. For example, in sectors such as textiles and food processing where heat is essential, biomethane could replace conventional fossil fuels, thus offering a decarbonized solution.

- Reduction of methane and CO2 emissions

One of the major advantages of methanisation is its ability to capture methane, a particularly powerful greenhouse gas, which would otherwise be released into the atmosphere during the decomposition of organic waste. This gas is converted into biogas, thus avoiding its escape and contributing to a reduction in global greenhouse gas emissions. By transforming this methane into energy, methanisation makes it possible to participate actively in the fight against global warming.

- Exploitation of biogenic CO2 in industrial processes

The CO2 produced by methanisation is biogenic and therefore carbon neutral, unlike fossil CO2. This CO2 can be captured and used in various industrial processes, such as the production of synthetic molecules or in the chemical industry. This valuation allows a circular use of carbon, contributing to the reduction of the carbon footprint of industrial sectors. For example, this CO2 can be used in the manufacture of chemicals or even in greenhouse cultivation processes, thus promoting an integrated and sustainable approach.

- Substitution in heavy industrial processes

Biomethane produced from methanisation can also replace fossil fuels in some heavy industrial processes, such as heat production for cement or metal manufacturing. These industries, known to be high CO2 emitters, can reduce their environmental impact by integrating biomethane as an alternative energy source. For example, in the metallurgical sector, where heat production is essential, the use of biomethane would significantly reduce CO2 emissions associated with the combustion of natural gas or coal.

- Use of biogenic CO2 in the production of green fuels

Biogenic CO2 from methanisation, combined with renewable hydrogen, can be used to produce synthetic fuels such as methanol or green diesel. These fuels can then be used in sectors that are difficult to decarbonize, such as maritime transport or aviation, which still depend heavily on fossil fuels. The use of biogenic CO2 in the production of synthetic fuels is therefore a promising prospect for decarbonisation in these sectors. Although these technologies are not yet widely deployed, they represent an important potential for the energy transition.

Challenges and opportunities

Although methanisation has many advantages, its large-scale deployment still faces several challenges. One of the main obstacles is the infrastructure needed to capture and develop biomethane at a competitive cost. The development of biogas plants and biomethane distribution networks seems to be largely conditioned by public policies and available economic incentives. Regulatory change could also encourage the use of biogenic CO2 in certain industrial sectors to optimize its role in decarbonisation.

Methanisation is thus a key technology for decarbonisation in the industry. In addition to helping reduce methane and CO2 emissions, it enables the production of renewable energy and green fuels. Its role in the exploitation of biogenic CO2 opens up promising prospects for industrial sectors that are difficult to electrify. However, in order to realize its full potential, it is crucial to overcome the challenges associated with its development, particularly in terms of infrastructure and regulation. By 2050, methanisation could play a central role in the energy transition and decarbonisation of industry, while contributing to the circular economy.

More news News