E-methanol, a decarbonisation vector in the chemical industry?

Source: ICF Insights, “How methanol can enable the hydrogen economy while adding value to captured carbon”

Methanol is a basic chemical widely used in various industrial sectors, including plastics, solvents, fuels and chemical processes. The production of methanol from fossil sources, such as natural gas, is responsible for a significant share of greenhouse gas (GHG) emissions. Approximately 1.7 tonnes of CO2 is emitted for each tonne of methanol produced by this method. This fossil-based mode of production thus contributes to the chemical industry’s emissions, in a context where the chemical industry is responsible for about 16% of global CO2 emissions. For these reasons, it is essential to seek solutions that reduce the carbon footprint of methanol production while maintaining its availability for industrial processes.

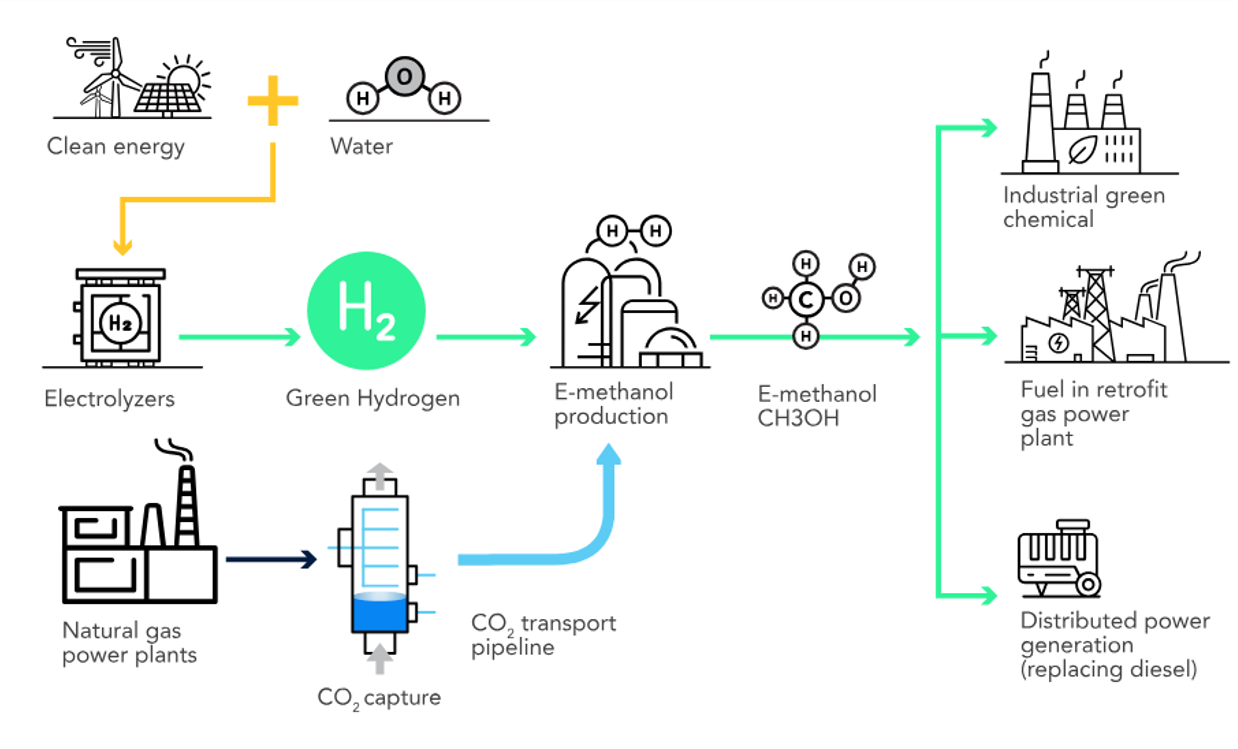

E-methanol (or green methanol) is an alternative to methane produced from fossil resources. E-methanol is manufactured using green hydrogen, produced by electrolysis of water, and CO2 captured directly from air or industrial sources. The use of this technology significantly reduces GHG emissions by replacing traditional natural gas-based production methods. The CO2 used in the production of e-methanol can come from renewable sources, creating a closed carbon cycle, reducing the overall impact of the production.

One of the main strengths of e-methanol is its ability to integrate into existing infrastructures, including traditional methanol production facilities. Indeed, the manufacturing processes of e-methanol are very similar to those used for fossil methanol, which facilitates the transition to a cleaner production without requiring major changes in industrial facilities. E-methanol can also be used in existing industrial applications, allowing for a gradual decarbonisation of dependent sectors such as the chemical industry, plastics production or fuel manufacturing.

Another important aspect of e-methanol is its potential in industrial processes with high carbon intensity, such as the production of heat and electricity. When used in power plants or industrial processes, e-methanol reduces CO2 emissions while ensuring continuity of energy production. It therefore represents an interesting transition solution for industries that are difficult to decarbonize, such as those requiring high temperatures for their manufacturing processes. Large-scale production of e-methanol could therefore make a significant contribution to reducing GHG emissions in key industrial sectors.

The prospect of large-scale production of e-methanol may, however, face some technical and economic challenges. The capture of CO2 and the production of green hydrogen require large investments and adapted infrastructures. If e-methanol could represent a promising solution for decarbonisation, its market competitiveness depends on the cost of these technologies, the price of carbon, as well as public policies to support the energy transition.

E-methanol represents an interesting prospect for the decarbonization of industry, offering a clean alternative to traditional methanol. If the technical and economic pitfalls are overcome, it could particularly contribute to the reduction of emissions from the production of chemicals (formaldehyde, acetic acid) and olefins (ethylene, propylene).

More news News