Can industrial ammonia production be decarbonized ?

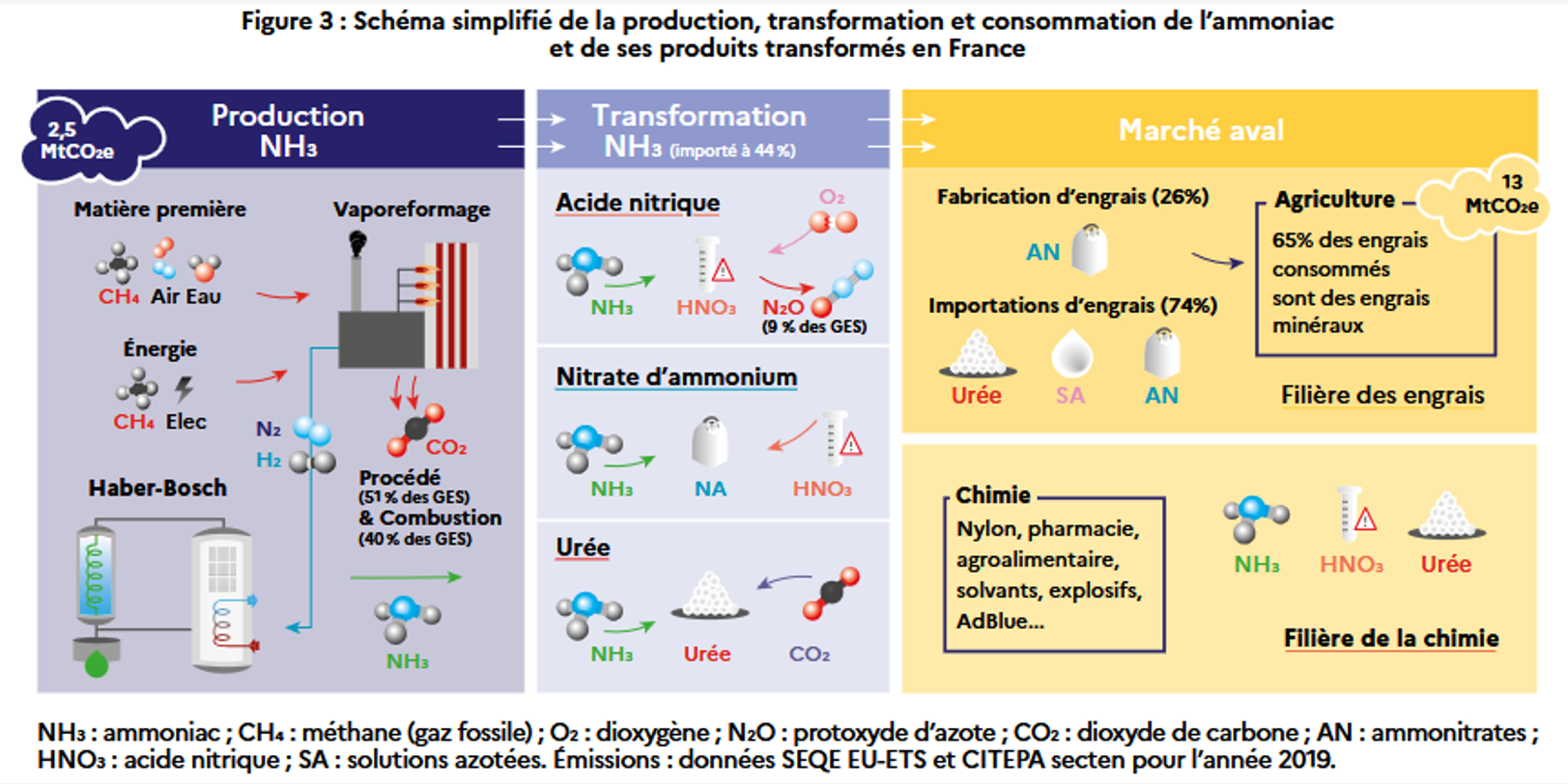

Source : Rapport de synthèse du Plan de Transition Sectoriel de l’Industrie de l’Ammoniac en France, p.8, ADEME, Septembre 2023

Ammonia is a versatile chemical compound (NH3) with many industrial applications:

- Mainly used for fertilizer production (80 to 90% of the produced ammonia is used to enrich agricultural soils).

- Key component in the production of many chemicals (nitric acid, polymers).

- Useful for industrial refrigeration due to its excellent cooling capacity and low cost.

- It also acts as an effective cleaning agent in various industries to treat surfaces and remove grease and dirt.

- Liquid ammonia is used in the textile industry for tanning and dye production.

- Liquid ammonia can also be used to produce green fuels for the transport sector (high energy density, hydrogen storage capacity): it can be used in internal combustion engines or fuel cells.

Currently, ammonia is mainly produced from fossil resources (gas, coal, naphtha, fuel oil). Industrial production of ammonia takes place in two main stages: the production of dihydrogen and the synthesis of ammonia. Dihydrogen is obtained by reforming methane (or other hydrocarbons such as coal and naphtha) with water vapour. Ammonia is then synthesized by a catalytic reaction between air dinitrogen and natural gas/hydrocarbon dihydrogen and water vapour. This industrial process of ammonia synthesis is known as the Haber-Bosch process. Ammonia production is responsible for 3% of French industry’s greenhouse gas emissions. The development of technologies to produce decarbonized ammonia could thus limit the environmental impact of this ubiquitous chemical in industry.

Two technological pathways are emerging to produce decarbonized ammonia:

- Carbon capture and storage (CCS) : Currently, some of the CO2 emissions from steam forming are already captured and used for urea production or sold to the food industry. The remainder could be liquefied and stored permanently, for example in the North Sea. However, capturing combustion emissions is more complex and costly due to their low concentration. The deployment of CCS on ammonia production sites poses economic, organizational and social challenges, but seems conducive to the configuration of industrial sites located in industrial areasports, since the possibility of pooling the necessary infrastructure and transport and easy access to offshore storage areas are important assets.

- Exclusive use of electrolytic hydrogen : This involves converting ammonia production sites to use exclusively hydrogen produced by electrolysis. This involves replacing the vaporeformer with electrolysers and an air separation unit to produce the hydrogen and nitrogen required for ammonia synthesis. This solution allows deep decarbonisation and reduces dependence on fossil gas, but requires a complete revision of the thermal integration of the site and maximum electrification of the equipment.

ADEME proposes in its Sectoral Transition Plan for the ammonia industry in France three prospective scenarios of decarbonisation of the sector, weighted according to different developments in agricultural models, international trade and technological choices made. These assumptions converge towards a structuring parameter: market transition, technological choices and planning and infrastructure needs will be essential to amplify decarbonization of the ammonia industry. The “resilience and renewable ammonia” scenario predicts a 98% reduction in GHG emissions through total decarbonization by hydrogen, which would still require significant investments.

More news News