NEWIRON Project

Production of sustainable steel by reducing iron ore using renewable hydrogen

Project coordinated by the CNRS

Duration of 4,5 years

3 millions euros of budget

Thesis

Context and challenges

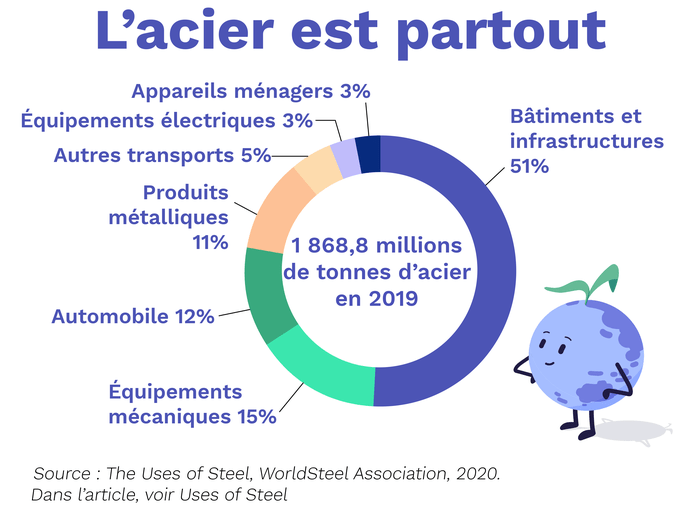

Steel is the basic material of modern civilisation. Although it promotes sustainability thanks to its high recyclability rates, its primary production has a significant negative impact on the environment. On average, each tonne of crude steel produced is accompanied by a staggering amount of approximately 2.1 tonnes of CO2. This enormous figure currently represents ~8% of all CO2 emissions on the planet and makes the iron manufacturing sector the largest industrial emitter of CO2. This is because iron is currently extracted from its ores using redox chemical reactions that use carbon-bearing substances as reducing agents, making CO2 the main by-product. To combat global warming, a drastic 80% reduction in all emissions by 2050 is necessary, and the most polluting sources must be tackled.

It is therefore imperative to urgently explore and implement new and sustainable ways of manufacturing iron in the coming decades.

Scientific objectives

The NEWIRON project aims to study the replacement of carbon with hydrogen-containing gases produced from renewable sources to serve as reducing agents for iron ores. In this case, water is the direct by-product rather than CO2. NEWIRON will focus particularly on three alternative routes, each of which currently has very different technology readiness levels (TRL): direct hydrogen-based reduction (DR), hydrogen plasma fusion reduction (HPSR), and solar hydrogen-based reduction (SDR) via concentrated solar heating. Here, we aim to address the emerging challenges in these pathways. With regard to fusion reduction, the increasing scarcity of high-grade iron ore concentrates poses difficulties for the production of high-quality pellets to feed blast furnaces.

Consequently, low-grade iron ores will have to serve as an alternative source of iron. NEWIRON proposes to study the direct reduction of iron ores with high impurity content (SiO2, Al2O3) in order to highlight competing secondary chemical transformations and their impact on overall reduction kinetics. Secondly, for economic and technical reasons, it is possible that some of the future green hydrogen will be transported in the form of ammonia (NH3), a high-density hydrogen carrier. The use of ammonia could also be advantageous in terms of activation temperature and frost protection.

The project teams will study the direct reduction of iron ore using ammonia (NH3). HPSR has only been studied in reactors with a single DC electrode. Here, we propose conducting HPSR experiments on a laboratory scale using a 3-electrode AC reactor. The need for such a study is obvious when considering adapting existing and already operational electric arc furnaces for hydrogen plasma purposes. Since HPSR only requires diluted H2 (max. 10% H2), the project seeks to identify and test alternative, inexpensive dilution gases, such as those produced by autothermal pyrolysis of biomass (CO, CO2, H2, CH4, N2). Direct use of solar energy is probably the path among the three where CO2 emissions could be lowest, although it is still in its infancy. NEWIRON proposes to build a pilot reactor to maximise reduction efficiency under concentrated solar irradiation using both H2 and NH3 as reducing agents.

The main objective of studying these three different pathways is to mitigate climate change and other environmental impacts. A life cycle assessment (LCA) and optimisation of each alternative process will be carried out (including reagent production, supply and storage, infrastructure and equipment construction). NEWIRON aims to provide scientific results to develop the TRL of these three alternative pathways and C-lean hydrogen-based reduction, thereby contributing to reducing CO2 emissions in the steel industry.

The consortium

More projects